How We Can Help You

Campbell Scientific data acquisition (DAQ) systems’ versatile capabilities make them ideal for structural health monitoring in a wide range of applications, including simple beam-fatigue, structural mechanics research, and continuous monitoring of large, complex structures. Campbell Scientific’s family of data loggers and DAQ systems are currently being used for remote, unattended, portable monitoring for highway overpasses, roads, buildings, retaining walls, bridges, and amusement park rides. Since 1974, Campbell Scientific has been known worldwide for rugged, accurate, and reliable measurement systems.

Watch the GRANITE™ Extreme Sensitivity video, the GRANITE™ Dynamic Range video, and the GRANITE™ Series Data Acquisition video.

Learn about our patented VSPECT® spectral-analysis technology at our VSPECT® Essentials web resource.

The dynamic vibrating-wire measurement technique is protected under U.S. Patent No. 8,671,758, and the vibrating-wire spectral-analysis technology (VSPECT®) is protected under U.S. Patent No. 7,779,690.

Learn moreCheck out some awesome examples of what our equipment can do in this area

Customize a System

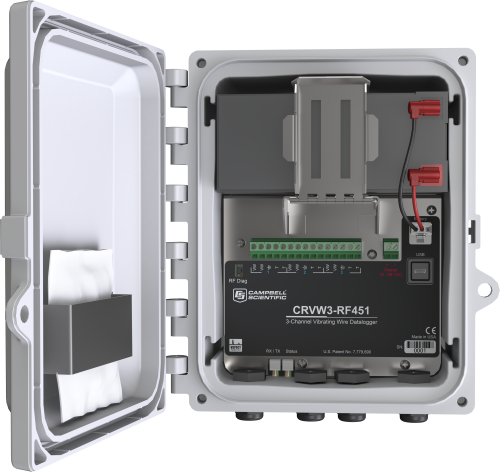

In addition to our standard systems available, many of the systems we provide are customized. Tell us what you need, and we’ll help you configure a system that meets your exact needs.

Related Product Categories

More Details about Our Structural Health Monitoring Systems

Data Acquisition (DAQ) Systems for Structural Monitoring and Control

The versatility of our modular DAQ systems allows them to be customized for each application.

Modular Design

The modular architecture of our GRANITE™ system allows each measurement module to independently connect to a PC or DAQ. As an independent module, the real-time measurements can be displayed directly on the PC. One or more measurement modules can be connected to the GRANITE DAQ to create the perfect networked configuration for each application. When connected, they form a time-synchronized, distributed DAQ system.

Distributed Networks and Synchronization

Multiple GRANITE measurement modules can be distributed throughout the structure. Each module is connected to a central GRANITE DAQ. This networking capability decreases the quantity and lengths of the sensor cables between the sensors and the GRANITE DAQ. Fewer sensor cables reduces cost, improves system simplification, and lessens the risk of signal corruption from noise.

Synchronization is key to the success of a distributed network. There are three significant levels to the GRANITE DAQ synchronization:

- The GRANITE DAQ has a built-in GPS and precision master clock.

- The pulse-per-second signal from the GPS is accurate to 1 µs. If enabled, the GRANITE DAQ will phase lock its operating clock to within 200 ns of the GPS clock. So, multiple independent DAQ systems spread over potentially vast geo-spatial regions can be synchronized with a maximum timing error between DAQ systems of 1.2 µs.

- Independent of the GPS, a temperature-compensated, high-precision, on-board, real-time clock will keep its own time with an accuracy of ±3 min/year.

- Within a single DAQ system, comprised of a GRANITE DAQ and GRANITE measurement modules, the measurements are all synchronized to the master clock of the GRANITE DAQ (sourced by either the GPS or precision on-board clock) via the CAN Peripheral Interface (CPI) or Ethernet Peripheral Interface (EPI) measurement buses.

- CPI synchronization between measurement modules in the same DAQ is ±5 µs. The overall physical range of the bus varies up to 2,000 ft depending on the data rate.

- EPI synchronization between measurement modules in the same DAQ is ±50 ns. The physical range of the bus is 300 ft per network connection. Daisy-chained connections can span thousands of feet.

- For extremely time-based-sensitive applications, the GRANITE SPECTRUM measurement modules are used with EPI synchronization. Within each module, the analog electrical signal delay is calibrated and compensated to reduce the timing delay mismatch to ±10 ns channel-to-channel.

Sensors Used in Structural Monitoring

Because Campbell Scientific data loggers and GRANITE DAQs are compatible with nearly every commercially available sensor, you can use the sensor that best meets your application. Typical sensors used for structural and seismic monitoring by our systems include:

- Carlson strain meters

- Vibrating wire strain gages

- Foil strain gages (set up in quarter-, half-, or full-bridge strain configurations)

- Inclinometers

- Crack and joint sensors

- Tilt sensors

- Piezoresistive accelerometers

- Piezoelectric accelerometers

- Capacitive accelerometers

- Borehole accelerometers

- Servo force balance accelerometers

Data Retrieval

Communication interfaces for retrieving, storing, and displaying data include direct connection to a PC or laptop, microSD cards, Ethernet, and several options for wireless communication (including built-in Wi-Fi).

Software

Our PC-based software options support connecting the GRANITE measurement modules directly to a PC or scheduling remote, automated data collection from the GRANITE DAQ. Real-time monitoring and control simplify the entire data-acquisition process, while robust error-checking ensures data integrity. We can even help you post your data to the Internet.

Example Application: Monitoring an Overpass

Campbell Scientific’s GRANITE monitoring systems are used for a variety of structural and seismic applications. Monitoring possibilities on an overpass could include:

Resources and Links

Product Brochures

Case Studies

Background In 2022, ECR Medio Ambiente assumed the responsibility of overseeing the structural monitoring installation at......read more

The Hong Kong-Zhuhai-Macao Bridge (HZMB)—comprising viaduct bridges, cable-stayed bridges, a submerged tunnel, and artificial islands—is......read more

GKM Consultants was contracted by a nationally leading engineering firm to develop, commission, and install......read more

Intelligent Infrastructure Systems, a Pennoni company, was contracted to design and install an efficient structural-health......read more

The Wolf Creek Dam near Jamestown, Kentucky, was constructed partially as a regular concrete hydroelectric......read more

The Confederation Bridge is one of the world's longest continuous pre-stressed-concrete, box-girder, bridges built over......read more

Ten Campbell Scientific CR10X dataloggers were used to monitor movement during the repair of the......read more

The Castillo de San Marcos National Monument, St. Augustine, Florida, is a 17th Century historic,......read more

FAQs for

Number of FAQs related to Structural Health Monitoring: 1

-

Most Campbell Scientific systems are built from individual components. This provides maximum flexibility for our customers, but it does not lend itself to pricing a "typical" system. Contact Campbell Scientific for assistance in pricing a system to meet the unique needs of the application.

Related Integrators

Associated Links

Articles and Press Releases

Newsletter Articles

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences