How We Can Help You

Our monitoring systems are used in mining operations worldwide to automate the data collection process of your sensors. The versatility, ruggedness, and reliability of Campbell Scientific monitoring systems make them ideal for geotechnical, water level, water quality, slope stability analysis, weather monitoring, ambient air quality, lightning warning, environmental compliance, dam and tailing monitoring, mine ventilation, equipment performance, cameras, and roof and shaft stability. Having a design that can operate in harsh remote locations—where unsafe conditions are often not suitable for personnel—and be reliable enough to keep people safe and mines open is absolutely a necessity. Campbell Scientific automated monitoring systems provide many benefits:

- Reduced resources (work hours, fuel, safety risks) required to have personnel manually collect data from sensors

- Increased data availability (data available 24/7)

- Improved data integrity

- Better worker and public safety

- Ability to monitor critical parameters even during shutdown or long-term care and maintenance

- Cost effective implementation of governance around environmental and safety solutions

Learn about our patented VSPECT® spectral-analysis technology at our VSPECT® Essentials web resource.

Learn about dynamic vibrating-wire at our Dynamic Vibrating-Wire web resource.

The dynamic vibrating-wire measurement technique is protected under U.S. Patent No. 8,671,758, and the vibrating-wire spectral-analysis technology (VSPECT®) is protected under U.S. Patent No. 7,779,690.

Learn moreCheck out some awesome examples of what our equipment can do in this area

Products

There are no active products in this category. See retired products below.

Customize a System

In addition to our standard systems available, many of the systems we provide are customized. Tell us what you need, and we’ll help you configure a system that meets your exact needs.

Related Product Categories

More Details about Our Mining Systems

Data acquisition, retrieval, and communication

Reliable data can be used to make prompt decisions that reduce risk and liability; promote health and safety; efficiently manage equipment, sites, or multiple assets; and ensure environmental compliance.

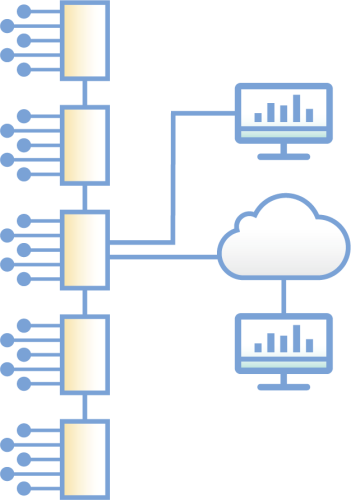

Our automated monitoring systems are capable of measuring virtually every commercially available sensor, then processing, storing, and transmitting the data to your cell phone, field office, or corporate headquarters. The automated collection of data from the sensor can then be communicated through radios, cellular modems, satellite modems, local networks, and the Internet. This accessibility allows for easy viewing and informed decision-making in response to changing conditions.

Alarms are easily integrated so you can suspend operations, move equipment, evacuate an area, or resume work. Systems can be programmed to send alarms or report site conditions by calling out to computers, phones, radios, or pagers.

Training

Campbell Scientific offers training courses that can be conducted at your location and customized to meet your specific needs. Hands-on training with our engineers helps ensure your system provides the site condition data you need today and into the future.

Application: Slope stability analysis

Slope stability data can be acquired from known problem areas or a network of monitoring systems strategically positioned around a mine. Common parameters used by our systems to monitor slope movement include lateral displacement, water level and flow, tilt, soil moisture, crack monitoring, and precipitation.

For more information, see the Slope Stability web page.

Application: Weather monitoring

Weather stations provide data that can be used to keep mining operations running when conditions warrant and to shut down when people and equipment need to be protected. Weather stations are often used to monitor wind speed and direction, air temperature, precipitation, barometric pressure, and relative humidity.

For more information, see the Automatic Weather Stations (AWS) and Meteorologic Instruments web page.

Application: Environmental compliance (air and water quality)

In surface and underground mining operations, there are often multiple air and water quality conditions that must be monitored to ensure compliance with environmental regulatory requirements.

Air quality and pollution monitoring systems automate data collection and reporting processes by measuring solar radiation, gases, particulates, atmospheric stability class, and other required parameters.

For more information, see the Air Quality and Pollution web page.

Regardless of salinity level, pollution level, or other harsh environmental conditions, our water quality monitoring and control systems are reliable. These systems measure all relevant parameters, including pH, conductivity, temperature, turbidity, dissolved oxygen, level, flow, and discharge. Specified time, event, or measured conditions can automatically trigger a water quality system to control various devices, such as pumps, mixers, valves, and gates.

For more information, see the Water Quality web page.

Application: Environmental, Social, and Governance (ESG)

Every mining organization is required to address Environmental, Social, and Governance (ESG) issues as part of their work within the marketplace and communities they serve. In the past, manual monitoring and visual inspection may have been good enough, but today the expectations are higher. Campbell Scientific continues to provide automated monitoring and control solutions for the mining industry to cost effectively implement governance around environmental and safety solutions in mines worldwide.

Other applications

Our versatile measurement and control systems are used in a variety of mining applications, including the following:

- Dam and tailings monitoring systems measure water level, flow, and turbidity; slope stability; and air and water quality.

- Mine ventilation systems measure barometric pressure, air temperature, relative humidity, and air velocity.

- Equipment performance systems keep mining equipment operating at peak performance levels by monitoring temperature, pressure, RPM, velocity, power, acceleration, position, torque, and strain.

- Roof and shaft stability systems are used to warn of possible cave-in conditions by monitoring changing conditions, cracks, and load distribution.

Resources and Links

Product Brochures

Case Studies

The Homestake Neutrino Experiment—also referred to as the “Davis Experiment” after physicist Ray Davis, who......read more

Background Tailings dams are crucial components of mining operations, responsible for storing water used in the......read more

Chevron Mining, Inc., (CMI) owned and operated a 6.6 million-metric-ton-per-year (6.6 million-U.S.-ton) molybdenum mining and......read more

Chevron Mining, Inc., (CMI) owned and operated a 6.6 million-metric-ton-per-year (6.6 million-U.S.-ton) molybdenum mining and......read more

Water and Earth Technologies (WET), a Campbell Scientific integrator, is a water resources and environmental engineering firm.......read more

Water and Earth Technologies (WET), a Campbell Scientific integrator, is a water resources and environmental engineering firm.......read more

RESPEC, a water-resources consulting and services firm, is currently under contract to operate and maintain......read more

In 1996, Southern Peru Copper Corporation (SPCC) installed real-time meteorological monitoring stations at its various......read more

FAQs for

Number of FAQs related to Mining: 6

Expand AllCollapse All

-

Yes. Campbell Scientific monitoring systems have a wide operating range, as low as -55°C and up to +85°C.

-

Campbell Scientific monitoring systems can communicate with a PC using several different methods, including cell modems, Wi-Fi, satellite, and radio. One common method is to use Campbell Scientific’s spread-spectrum radios to transmit the data over tens of kilometers back to a server. The monitoring stations can act as repeaters to repeat the data stream to easily overcome long distances or line-of-sight obstructions.

-

Yes. Satellite modems are often used to provide communications when other services are available.

-

Almost any sensor type can be measured by a Campbell Scientific monitoring system due to our open architecture and flexible design: voltage output, vibrating-wire, resistive, digital, and more.

-

No. For example, a typical geotechnical monitoring system that reads up to 16 geotechnical sensors can be powered year-round by a battery about the size of a motorcycle battery along with a 20-watt solar panel.

-

Yes. The monitoring system needs to be connected to the sensor wires, but small-scale/low-cost monitoring systems make it cost effective to put systems on single sensors.

Related Integrators

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences